Sustainable Packaging Solutions with Wet-Pressed Molded Pulp #

Wet-pressed molded pulp is an environmentally conscious packaging material crafted from natural plant fibers. Utilizing renewable resources such as recycled paper pulp, bagasse, bamboo pulp, or wood fibers, this material is shaped while still wet. Through a process of high-temperature and high-pressure molding, it achieves a precise form with a smooth, refined surface. Today, wet-pressed molded pulp is widely adopted for premium inner packaging in smartphones, 3C electronic devices, tablets, and more, making it a preferred sustainable solution for leading international technology brands.

Features of Wet-Pressed Molded Pulp #

Wet-pressed molded pulp trays are paper-based products manufactured through wet forming processes. Their key characteristics and applications include:

-

High Strength and Durability

Engineered with specialized processing techniques, wet-pressed trays offer excellent strength and durability, capable of withstanding considerable weight and pressure. -

Superior Moldability

The wet forming process allows for versatile shaping, enabling the creation of various forms and structures with high design flexibility. -

Eco-Friendly and Biodegradable

Made from naturally degradable paper materials, these trays meet environmental standards and decompose without polluting the environment.

Advantages: Wet-Pressed vs. Dry-Pressed Molded Pulp #

-

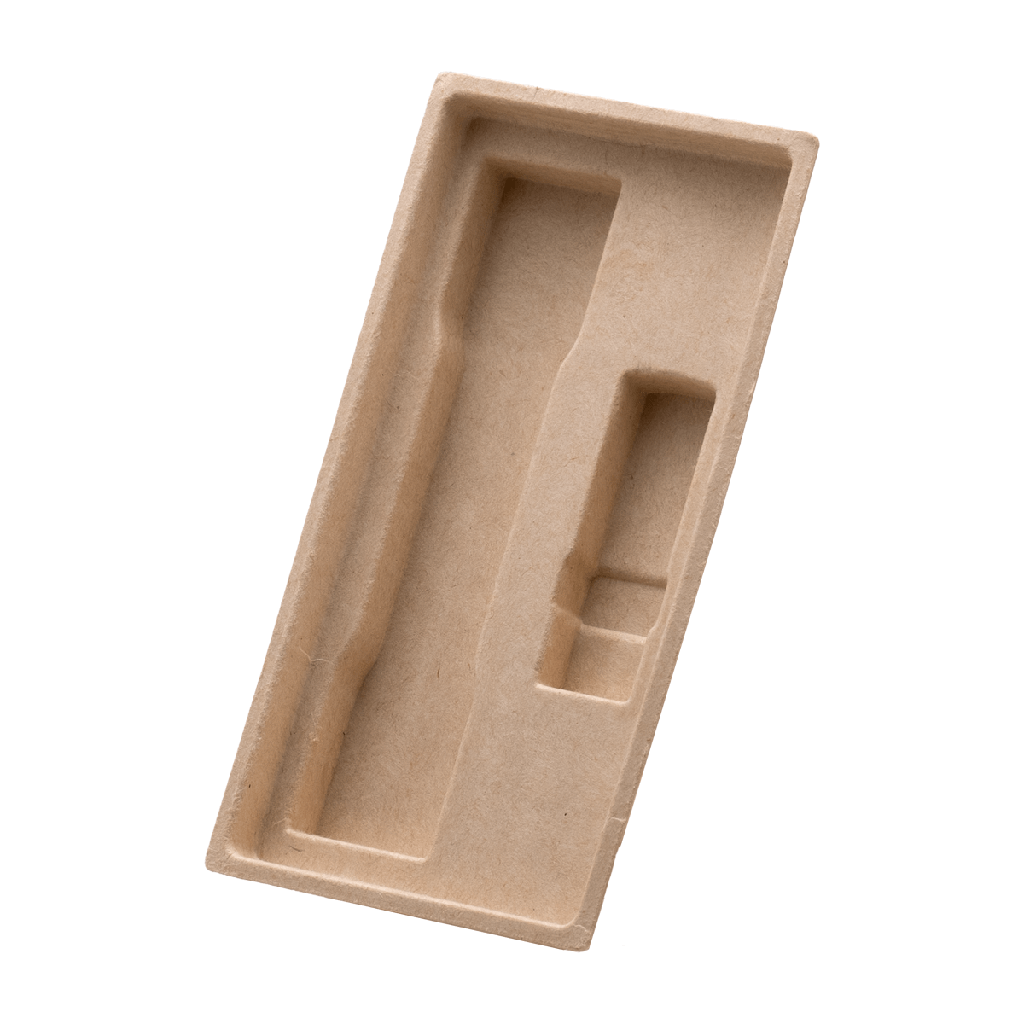

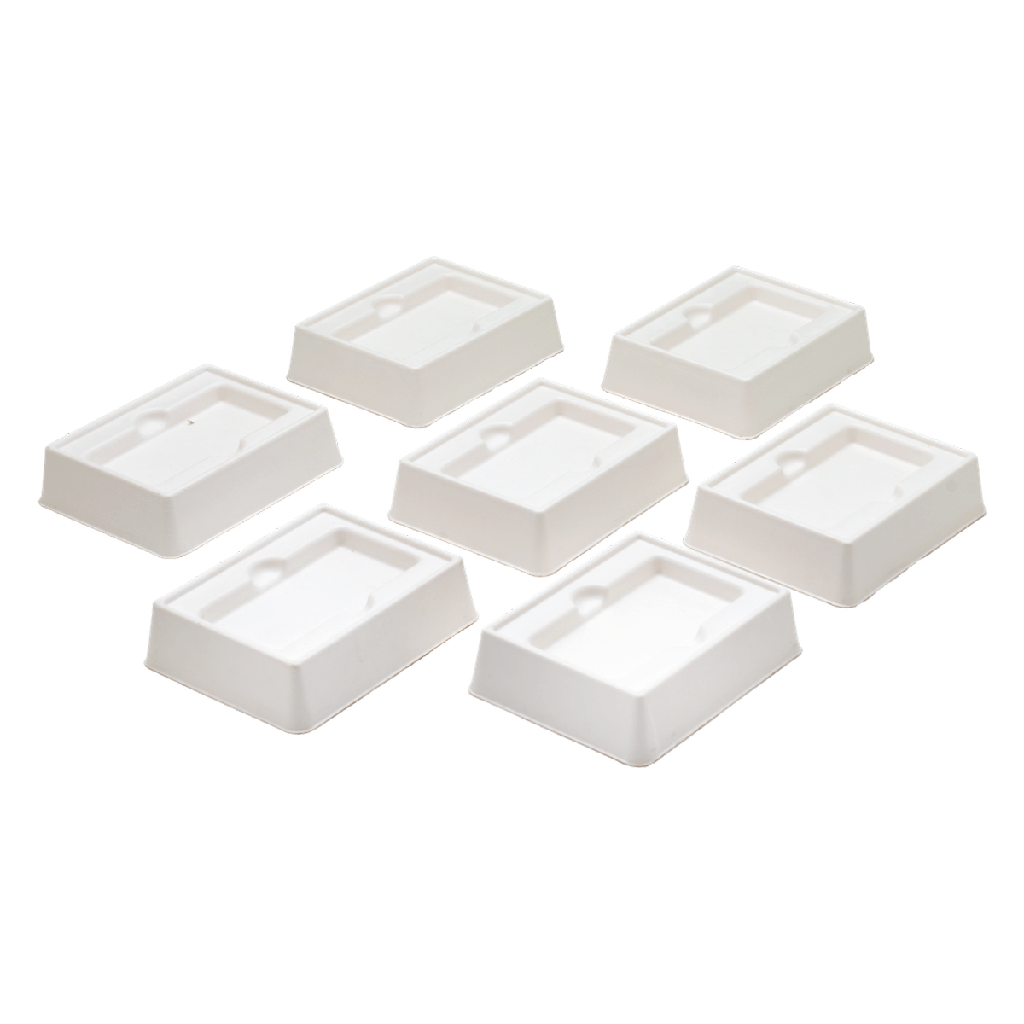

Appearance

Wet-pressed trays feature a smooth finish on both sides, molded precisely between top and bottom dies. The surface is sleek, free from roughness or lint. -

Product Precision

With CNC-machined molds, minimal corner radii down to 20° are achievable with exceptional accuracy—ensuring snug protection for every product contour, much like a well-fitted garment. -

Moisture Resistance

Thanks to a controlled drying process, the trays retain minimal moisture, preventing deformation during storage due to humidity. -

Raw Materials

Crafted from bagasse, wood pulp, and various plant fibers, the materials are environmentally friendly and available in multiple colors to suit different preferences.

Application Fields #

- Food Packaging: The strength and absorbency of wet-pressed pulp trays make them ideal for packaging frozen foods, fresh produce, and more.

- Agricultural Use: These trays are suitable as seedling trays or plant bedding, providing a nurturing environment for growth.

- Medical Supplies: Widely used in packaging medical devices to ensure hygiene and cleanliness.

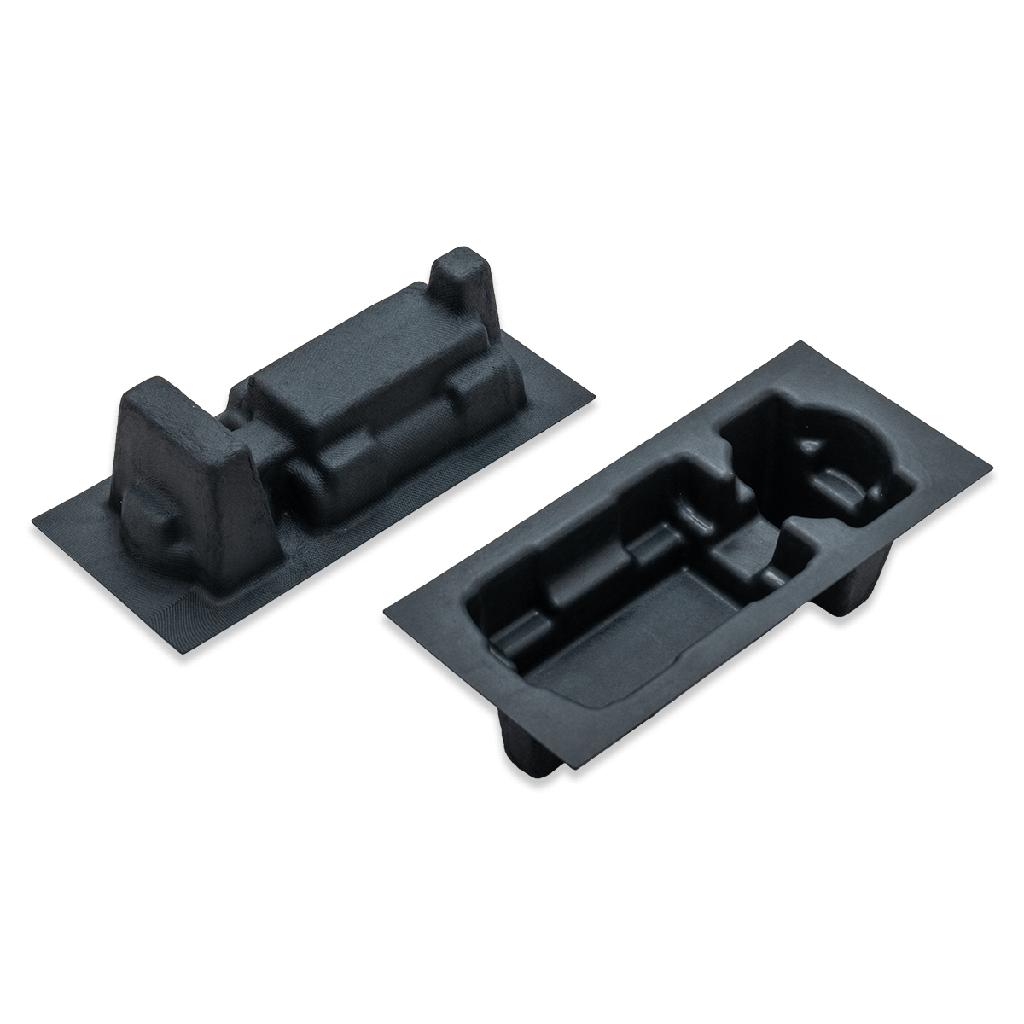

- Electronics (3C) Packaging: Valued for their anti-static properties and refined appearance, wet-pressed trays are favored by major global electronics brands. Available in brown, white, and black for premium 3C product packaging.

- Industrial Packaging: Suitable for securing components during transport, protecting them from damage.

For further information or to discuss your packaging needs, please contact us.

Food Packaging

Food Packaging Agricultural Use

Agricultural Use Medical Supplies

Medical Supplies Electronics (3C) Packaging

Electronics (3C) Packaging Industrial Packaging

Industrial Packaging